Waterjet Cutting Redefines Commercial Flooring

Commercial flooring is more than creating surfaces. It presents a canvas for creativity. With waterjet cutting, the door opens to unleash creativity at new heights. It redefines the world of commercial flooring.

The technology enables you to create unique patterns, logos, and designs with great precision on a variety of materials. So, you can take VCT, LVT, heterogeneous, and homogeneous sheet flooring designs to all new levels

If you’re a designer or architect, waterjet technology opens incredible possibilities. Now, you can make even bolder statements with your commercial flooring designs.

The process continues to gain popularity. Manufacturing Solutions reports that the waterjet cutting machine market is expected to grow at a compound annual growth rate (CAGR) of 5.1% through 2027.

What Is Waterjet Cutting?

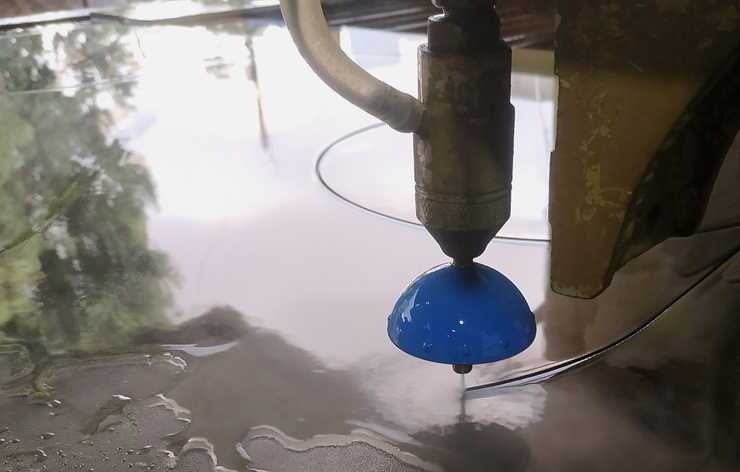

Waterjet cutting is an advanced process that uses pressurized water. The water mixes with abrasive particles to cut through numerous materials, including metals, plastics, rubbers, composites, and glass.

When forced through a cutting head, water becomes a powerful abrasive jet capable of delivering clean and precise cuts. For example, water jetting is up to four times more accurate than a plasma cutter.

The process is also more efficient than other cutting methods. You can cut materials up to 10 times thicker than those cut by laser cutting. Moreover, you can stack materials on top of each other to reduce cutting time.

Computer controls manage the cutting process to ensure accuracy, even for the most intricate designs.

Types of Waterjet Cutters

Waterjet technology isn’t new. Coal miners first used it in hydraulic mining in the mid-19th century. The technology advanced in the 1970s with improvements to the waterjet nozzle, enabling pressures of up to 70,000 psi.

The two types of waterjet cutting are pure waterjet and abrasive waterjet. The pure version utilizes only water to cut soft materials, such as paper, rubber, foam, wood, and carpet. It doesn’t include a mixing chamber or nozzle.

The abrasive waterjet includes an abrasive to boost cutting power. The abrasive and water combine in a mixing chamber in the cutting head before the jet exits the system. Abrasive waterjet cutting is well-suited for handling more rigid materials, such as stone, ceramic, glass, and metal.

How Do Jet Cutters Work?

Ultra-high-pressure pumps, which contain a pump and a cutting head, generate a powerful cutting stream, ranging from 30,000 to 90,000 psi during the cutting process.

The mixing tube combines water and abrasive particles at the nozzle. Popular materials include grit, garnet powder, and aluminum oxide. The nozzle directs the abrasive jet stream to slice through the material accurately. As mentioned, you can remove the abrasive element when cutting softer materials.

The beam created is exceptionally narrow, contributing to the precision of the cut. For example, many waterjet machines offer a cutting tolerance of 0.05 mm, with others providing even lower tolerances.

Equally important, the machine head doesn’t contact the material’s surface. This helps to prevent increases in the material’s temperature, which can compromise its structural integrity. Waterjet technology uses a cold-cutting process.

Why Choose Waterjet Cutting for VCT Flooring?

VCT is a popular flooring option known for its durability and versatility. Waterjet cutting enhances the functionality of VCT, offering endless possibilities for creating customized designs.

Water jet cutters can produce intricate cuts in material. Using specialized software and 3D machining heads, you can create complex shapes, substantially expanding design options.

Here’s why waterjet cutting machines are ideal for VCT and other commercial flooring types:

A Jet Cutter is Precise

The jet cutter delivers smooth edges and perfect shapes with no burn marks, cracking, or excess burrs. The narrow water beam produces a clean finish, eliminating the need for edge cleanup. Equally important, the process maintains exceptionally tight tolerances, enabling the creation of more intricate designs without compromising accuracy or speed.

For designers and architects, waterjet technology unlocks an endless array of creative possibilities. It allows you to craft stunning flooring designs for any space, from corporate offices to schools and retail stores.

Logos, patterns, or complex images can be added to commercial flooring projects. For example, you can easily insert a picture of a school’s mascot or company logo onto the VCT.

The process also allows for seamless integration. So you can combine colors and shapes with smooth, professional transitions.

Water Cutting Produces Minimal Waste

Precision cutting ensures nearly full use of all materials. Additionally, the process utilizes only natural resources, such as water and sand, to minimize the environmental impact of the cutting process. Other methods can use chemicals, heat, oils, or products that create toxic fumes.

Waterjet Cutting Doesn’t Compromise the Material

Cutting processes that generate heat can create a heat-affected zone (HAZ). Plasma, lasers, or torches used in these processes melt the material during cutting, impacting the material’s inherent structure.

Waterjetting employs a cold-cutting process to preserve the material’s properties. Thus, the final product has superior edge quality and is less likely to warp. It’s also less likely to have weak points that can compromise its quality.

Where to Use Waterjet-Cut VCT Flooring

The versatility of waterjet technology makes it an ideal choice for a wide range of applications. Some examples include:

Corporate Offices

- Embed logos into the floor for branding.

- Create patterns to guide foot traffic or define areas.

Educational Spaces

- Feature mascots, school mottos, or themed designs in hallways and common areas.

- Use custom patterns to designate zones or pathways.

Healthcare Facilities

- Add soothing designs to create a calming environment for patients.

- Utilize wayfinding designs to help visitors navigate the space effectively.

Retail & Hospitality

- Impress customers with bold, artistic designs.

- Add seasonal or event-based patterns for a fresh, dynamic look.

No matter what the setting, waterjet-cut VCT flooring transforms spaces with personalized and functional designs.

Using Waterjet in Your Next Flooring Project

This powerful cutting method combines precision, creativity, and sustainability to deliver beautiful, unique floors. As a long-standing leader in commercial flooring, AHF Contract® can help bring it to life in your next project.

Contact a rep today to learn more and start your custom flooring project.